| Model | BL – YTE100T1 | BL – YTE200T2 | BL – FTE100T1 |

| Product Name | Blast Freezer: Single-Door Trolley Roll-in | Blast Freezer: double-Door Trolley Roll-in | Blast Freezer: Remote Single-Door Trolley Roll-in |

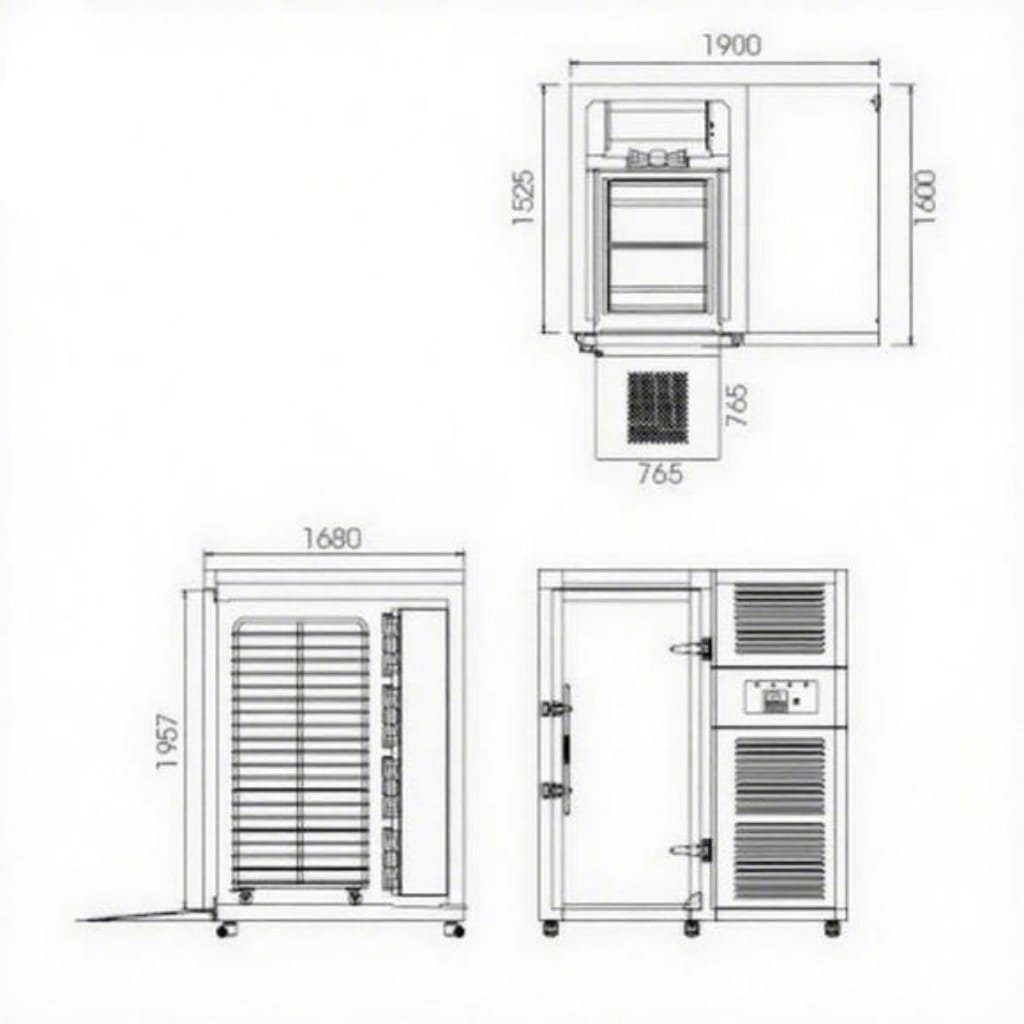

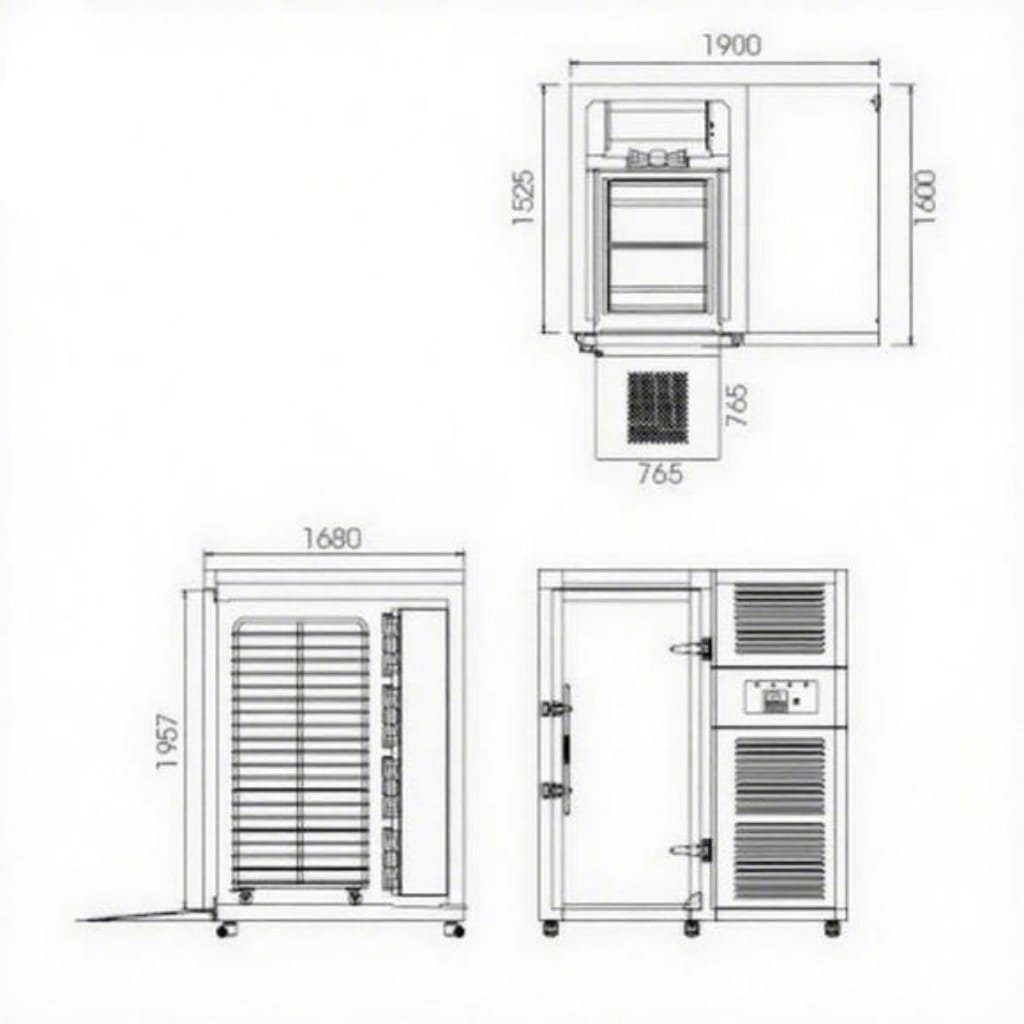

| Dim (W×D×H, mm) | 1900 x 1680 x 2150 + 100 | 3160 x 1680 x 2150 + 100 | 1450 x 1250 x 2150 + 100 |

| Dim (W×D×H, in) | 74.8 x 66.1 x 84.6 + 3.9 | 124.4 x 66.1 x 84.6 + 3.9 | 57.1 x 49.2 x 84.6 + 3.9 |

| Voltage (V) | AC380V 3P ~ 50HZ | AC380V 3P ~ 50HZ | AC380V 3P ~ 50HZ |

| Power (kW) | 12 | 20 | 12 |

| Volume | 40 trays (for 600x400mm trays) | 80 trays (for 600x400mm trays) | 40 trays (for 600x400mm trays) |

| Temperature (°C) | +3 ~ – 50°C (Operating temp: – 35 ~ – 40°C) | +3 ~ – 50°C (Operating temp: – 35 ~ – 40°C) | +3 ~ – 50°C (Operating temp: – 35 ~ – 40°C) |

| Temperature (°F) | +37.4 ~ – 58°F (Operating temp: – 31 ~ – 40°F) | +37.4 ~ – 58°F (Operating temp: – 31 ~ – 40°F) | +37.4 ~ – 58°F (Operating temp: – 31 ~ – 40°F) |

| Capacity per cycle | ≤100 KG / H | ≤200 KG / H | ≤100 KG / H |

| Cooling type | Air-Cooled | Air-Cooled | Air-Cooled |

| Refrigerant | R – 404a / R – 507 | R – 404a / R – 507 | R – 404a / R – 507 |

| Heat dissipation mode | External unit (Air – cooled / Water – cooled) | External unit (Air – cooled / Water – cooled) | External unit (Air – cooled / Water – cooled) |

| Trolley size (mm) | 670x850x1760 | 670x850x1760 | 670x850x1760 |

| Trolley size(in) | 26.4 x 33.5 x 69.3 | 26.4 x 33.5 x 69.3 | 26.4 x 33.5 x 69.3 |

| Platform size(mm) | 765×765 | 765×765 | 765×765 |

| Platform size(in) | 30.1 x 30.1 | 30.1 x 30.1 | 30.1 x 30.1 |

Specifications subject to change without notice.

Design

- Specifically engineered for food workshop layouts, the roll-in trolley design streamlines workflow by integrating seamlessly with production lines, reducing manual handling and transportation costs. Suitable for both collective catering (large-scale meal preparation) and industrial production needs, it enhances operational efficiency.Available in integrated (unit + cabinet) or split-unit configurations to adapt to diverse workshop spaces and installation requirements. Customization services are offered, including adjustable capacities and dimensions, to fit specific production scales and spatial constraints.

Refrigeration System

- The factory - independently designed capillary system utilizes an eco - friendly R290 hydrocarbon refrigerant (with zero ODP and low GWP), significantly cutting down greenhouse gas emissions to contribute to achieving “carbon neutrality”.

- Achieves a wide cooling range of +3°C to -50°C, with stable operating temperatures between -35°C and -40°C, ensuring consistent freezing results.

- Three specialized cooling modes:

- +3°C "soft" rapid cooling: Ideal for delicate or thin foods such as rice, vegetables, and fried items, preserving texture without over-freezing.

- +3°C "hard" rapid cooling: Suitable for thick, oily, or large-sized foods, ensuring thorough cooling without core temperature lag. .

- -18°C flash freezing: Quickly passes through the critical zone of large ice crystal formation, minimizing cell damage—perfect for pasta, frozen baked goods, livestock/poultry products, and pre-prepared dishes

- High freezing efficiency: 100~200kg/h, designed for continuous large-batch production in food factories.

- Compared to liquid nitrogen freezers, it features high automation and reduces costs by up to 80%, optimizing long-term operational expenses.

Cabinet Construction

- Exterior and interior constructed with high-quality stainless steel, offering superior corrosion resistance, easy cleaning, and durability in high-moisture, high-frequency production environments.

- High-density insulation materials minimize cold loss, ensuring stable low-temperature operation and energy efficiency.

Trolley & Tray Compatibility

- Designed for roll-in trolleys, enabling seamless loading/unloading of trays, reducing manual labor and improving workflow efficiency.

- Fits 40 standard 600x400mm trays, with an optional 80-tray high-capacity model.

Doors

- Large, easy-to-operate doors with excellent sealing performance to prevent cold air leakage, maintaining stable internal temperatures.

- Designed for smooth trolley entry/exit, with durable hinges supporting frequent use in busy production environments.

Model Features

- Intuitive control system with clear digital displays, allowing real-time monitoring of temperature and operation status.

- Indicator lights for different cooling modes (soft rapid, hard rapid, flash freezing) for straightforward operation.

Electrical

- Pre-wired for industrial power supply (380V as standard, other specifications available upon request) with 50Hz frequency, compatible with commercial production facilities.

- Standard plugs compliant with regional standards (European, British, etc.) available upon request.

Optional Features/accessories Upcharge And Lead Times May Apply.

- Optional high-capacity model, fitting 80 pcs of 400x600mm trays

- Split-unit configurations for workshops with space constraints.

- Enhanced insulation thickness for extreme low-temperature requirements.