Cooling Type:Air-Cooled

Model | LF050C2 | LF100C4 | LF150C6 | LF050D2 | LF100D4 | LF150D6 | LF100C2D2 | LF150C4D2 |

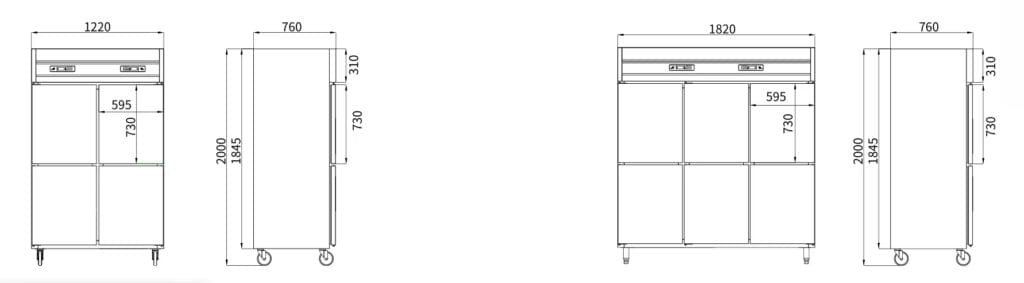

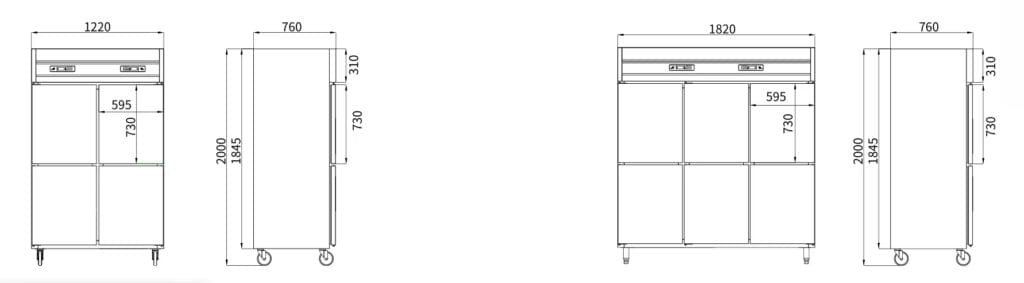

Dimension(mm) | 620×760×2000 | 1220×760×2000 | 1820×760×2000 | 620×760×2000 | 1220×760×2000 | 1820×760×2000 | 1220×760×2000 | 1820×760×2000 |

Imperial(inch) | 24 13/32 × 29 15/16 × 78 3/4 | 48 3/32 × 29 15/16 × 78 11/16 | 71 5/8 × 29 15/16 × 78 3/4 | 24 13/32 × 29 15/16 × 78 3/4 | 48 3/32 × 29 15/16 × 78 11/16 | 71 5/8 × 29 15/16 × 78 3/4 | 48 3/32 × 29 15/16 × 78 11/16 | 71 5/8 × 29 15/16 × 78 3/4 |

Temp.(℃/°F) | 0~5℃/32~41°F | 0~5℃/32~41°F | 0~5℃/32~41°F | – 12~-18℃ / 10.4~-0.4°F | – 12~-18℃ / 10.4~-0.4°F | – 12~-18℃ / 10.4~-0.4°F | 0~5℃,-12℃~-18℃/32~41°F,10.4~-0.4°F ) | 0~5℃,-12℃~-18℃/32~41°F,10.4~-0.4°F ) |

Volume(L) | 500L | 1000L | 1500L | 500L | 1000L | 1500L | 900L | 1350L |

Power(W) | 400W | 600W | 800W | 600W | 1000W | 1300W | 900W | 1200W |

fast cooling, precise temperature control, frost-free and maintenance-free design, good freshness preservation, and flexible storage space. | ||||||||

Cooling Type:Direct-Cooled

| Model | LZ050C2 | LZ100C4 | LZ150C6 | LZ050D2 | LZ100D4 | LZ150D6 | LZ100C2D2 | LZ150C4D2 |

| Dimension(mm) | 620×760×2000 | 1220×760×2000 | 1820×760×2000 | 620×760×2000 | 1220×760×2000 | 1820×760×2000 | 1220×760×2000 | 1820×760×2000 |

| Imperial(inch) | 24 13/32 × 29 15/16 × 78 3/4 | 48 3/32 × 29 15/16 × 78 11/16 | 71 5/8 × 29 15/16 × 78 3/4 | 24 13/32 × 29 15/16 × 78 3/4 | 48 3/32 × 29 15/16 × 78 11/16 | 71 5/8 × 29 15/16 × 78 3/4 | 48 3/32 × 29 15/16 × 78 11/16 | 71 5/8 × 29 15/16 × 78 3/4 |

| Temp.(℃/°F) | 0~5℃/32~41°F | 0~5℃/32~41°F | 0~5℃/32~41°F | – 12~-18℃ / 10.4~-0.4°F | – 12~-18℃ / 10.4~-0.4°F | – 12~-18℃ / 10.4~-0.4°F | 0~5℃,-12℃~-18℃/32~41°F,10.4~-0.4°F ) | 0~5℃,-12~-18℃/32~41°F,10.4~-0.4°F |

| Volume(L) | 500L | 1000L | 1500L | 500L | 1000L | 1500L | 900L | 1350 |

| Power(W) | 300W | 500W | 700W | 500W | 900W | 1100W | 800W | 1000W |

| Simple structure for easy maintenancelow cost, e*cellent humidity retention, low noise, and lower energy consumption, but requiring regular defrosting | ||||||||

Specifications subject to change without notice.

Design

- ICOLDBOX is committed to using high-quality materials and efficient refrigeration systems, continuously updating production processes and technologies to provide users with lower product temperatures, lower usage costs, excellent food safety, and the best personalized customization services to achieve the most suitable solutions.

Refrigeration System

- factory's independently designed capillary system uses eco-friendly R290 hydrocarbon refrigerant (zero ODP, low GWP), significantly reducing greenhouse gas emissions to aid in achieving "carbon neutrality".

- The mature and high-quality refrigeration system is equipped with a branded compressor, featuring high refrigeration efficiency and energy-saving emission reduction.

- The optional variable-frequency temperature sensor enables precise temperature control within 1°C inside the cabinet, ensuring optimal food preservation.

- Copper tube fin heat dissipation rapidly dissipates heat, keeping equipment at optimal working temperature to boost efficiency and enhance stability/reliability.

- The condensing unit is mounted on the top for more uniform cooling, leaving more storage space at the bottom.

Two refrigeration methods are available:

Air-cooled refrigeration: Features fast cooling speed, precise temperature control, frost-free and maintenance-free operation, excellent fresh-keeping effect, and more flexible storage space. The price and operating noise are slightly higher than those of direct-cooled refrigeration.

Direct-cooled refrigeration: Boasts a simple structure for easy maintenance, low cost, good moisture retention, low noise, and relatively low energy consumption. However, regular defrosting is required.

Cabinet Construction

- Exterior visible parts are made of high-quality stainless steel. The back, top and bottom panels are made of galvanized sheets (full stainless steel is also optional).

- Interior is made of high-quality stainless steel, anti-corrosive, durable and easy to clean.

- Insulation - The entire cabinet structure and solid doors are foamed on - site with high - density polyurethane insulation material, which has zero Ozone Depletion Potential (ODP) and Global Warming Potential (GWP).

- High-quality stainless steel heavy-duty frame rails with multiple PVC-dipped wire shelves: durable, corrosion-resistant, and freely adjustable.

Doors

- Stainless steel housing with fine sandblasted finish ensures a smooth, aesthetically pleasing appearance that's easy to clean.

- Sealed self-closing door with high-quality detachable & cleanable door seals ensures excellent sealing to prevent cold air leakage.

- Magnetic door hinge chain; automatic return hinge with positive sealing self-closing function and 120° open hold feature.

Shelving

- Each section is equipped with 3 height-adjustable heavy-duty PVC-dipped wire shelves. Shelf support pillars are made of the same material as the cabinet interior.

Lighting

- Optional interior LED lighting

Model Features

- External digital temperature display with selectable Fahrenheit (°F)/Celsius (°C).

- Evaporator with optional epoxy resin coating for anti-corrosion and durability.

Electrical

- The equipment is factory pre-wired for direct connection to a single-phase 220V power supply with 10A/16A dedicated sockets. Includes power cord and plug kit.

- Standard triangular plug (connectors compliant with relevant standards of different countries are available).

Optional Features/accessories Upcharge And Lead Times May Apply.

- Refrigeration method optional (direct-cooled or air-cooled)

- Variable frequency temperature sensor (optional)

- Evaporator with optional epoxy resin coating

- Optional interior LED lighting

- Additional shelves (stainless steel version optional)

- Supports and casters customizable as required

- Connectors customizable for European, British standards, etc.

- Optional stainless steel back/top/bottom panels (STR/STA/STG)

- Shape, thickness, material, cooling method, and internal structure all customizable